What Is an Inventory Control System (ICS)?

An Inventory Control System (ICS) is a strategic, data-driven framework designed to manage, monitor, and optimize an organization's inventory levels throughout its entire supply chain.

By employing a combination of software applications (like an inventory management system), hardware tools, and standardized processes, an ICS seeks to balance the need for efficient stock management with the objectives of cost reduction, customer satisfaction, and profitability. Its primary functions include demand forecasting, stock replenishment, stock classification, and inventory tracking, which, when synchronized, contribute to more informed decision-making and operational excellence.

Key Components of an Inventory Control System

- Demand Forecasting. This process involves the use of historical data, market trends, and statistical models to predict future demand patterns for products. Accurate demand forecasting is crucial for maintaining optimal inventory levels and minimizing stockouts or overstock situations, which can negatively impact customer satisfaction and cash flow.

- Stock Replenishment. This function ensures that adequate quantities of inventory items are ordered and received in a timely manner to meet customer demand. Inventory control systems utilize replenishment techniques such as Economic Order Quantity (EOQ), reorder point, and safety stock calculations to optimize ordering frequency and quantities.

- Inventory Tracking and Visibility. ICS solutions use various technologies, such as barcoding, RFID, and IoT, to track inventory throughout the supply chain in real time. This comprehensive visibility enables organizations to monitor stock levels, identify discrepancies, and streamline their warehousing and logistics operations.

- Stock Classification. The ABC analysis, a widely adopted inventory classification technique, categorizes items based on their monetary value and demand frequency, allowing businesses to prioritize their inventory management efforts. This approach helps organizations to focus on high-value items, reduce carrying costs, and improve overall inventory efficiency.

- Reporting and Analytics. Advanced inventory control systems generate real-time reports and analytics that provide valuable insights into inventory performance, such as turnover rates, stockout occurrences, and holding costs. These data-driven insights aid decision-making and facilitate continuous improvement of inventory management practices.

Benefits of an Inventory Control System

- Reduced Stockholding Costs. By maintaining optimal inventory levels and minimizing excess stock, organizations can reduce carrying costs, such as storage, insurance, and obsolescence expenses.

- Improved Customer Satisfaction. Timely and accurate fulfillment of customer orders is essential for maintaining customer loyalty and trust. An ICS helps prevent stockouts and backorders, ensuring a seamless customer experience.

- Enhanced Cash Flow. Efficient inventory management frees up working capital by reducing the amount of capital tied up in inventory, thereby improving cash flow and overall financial performance.

- Increased Operational Efficiency. By automating manual processes, streamlining warehouse operations, and providing real-time visibility into inventory levels, an ICS contributes to more efficient resource utilization and higher productivity.

- Informed Decision-making. Access to real-time data and analytics enables organizations to make proactive, data-driven decisions that align with their strategic objectives and contribute to long-term success.

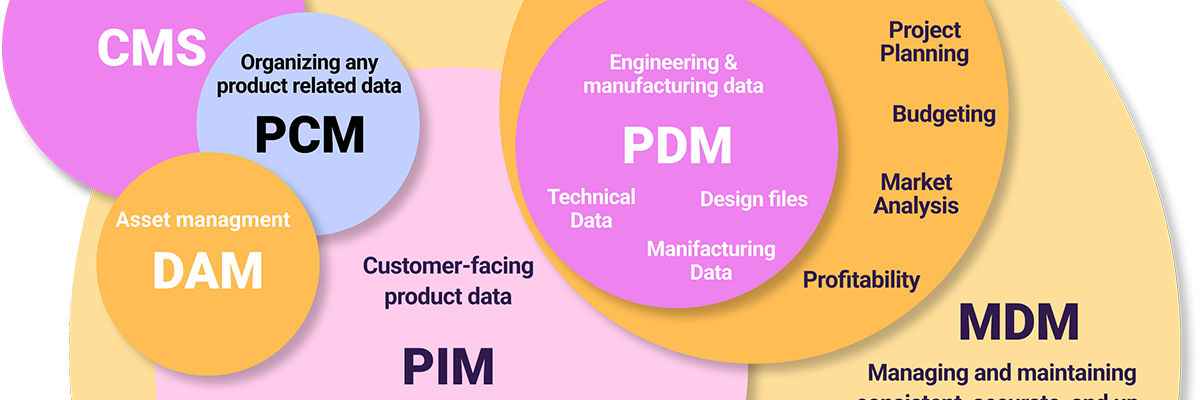

📑Managing Product Data and Tools You May Need Infographic.

What is PIM, and how different is it from other similar tools? We’ve tried to clear up the acronym confusion in eCommerce with the following infographic that provides you with a visual comparison of all relevant terms. Individual posts dig deeper into each term and the concept behind it.

📝READ WHAT IS PIM AND DOWNLOAD THE INFOGRAPHIC FOR FREE FROM HERE

Today Inventory Control System is a crucial element in effectively managing an organization's inventory.